Services

Our production range is highly diversified, and therefore we can provide the best solutions to the complex requirements coming from the market.

In fact, G.ELLI RIDUTTORI SEITES S.r.l. is able to serve the different needs related to applications in the field of the power transmission by means of gears, such as:

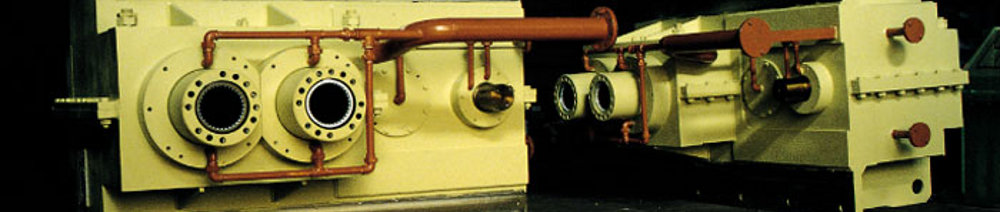

- special gearboxes and speed increasers expressly designed to comply with the layout the needs of the application

- gearboxes based upon our catalogue, possibly adapted to the specific needs of the customers. This category includes:

- gearboxes manufactured in compliance to the customer’s drawings

- modifications, revamping and maintenance interventions on any kind of gearbox, also if not manufactured by ourselves

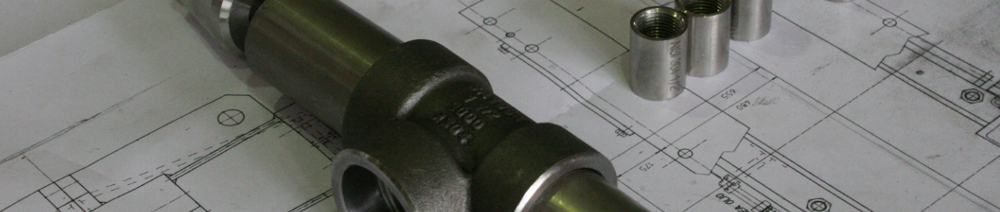

We also own the technical archives of the company “Sacerdoti”, and therefore we can supply spare parts or whole gearboxes perfectly interchangeable to the ones originally manufactured by that company, which is no longer on the market. As regards the supply of spare parts, we can manufacture spare gears according to our design, or according to the customer’s drawings, or expressly designed to fit special applications.

- helical gears in case hardened and tempered steel or in through hardened steel, also double-helical

- Gleason or Klingelnberg type bevel gears in case hardened and tempered steel, finished by lapping or grinding

- special couplings, with dimensions different from the catalogue or with special details such as the engaging/disengaging device

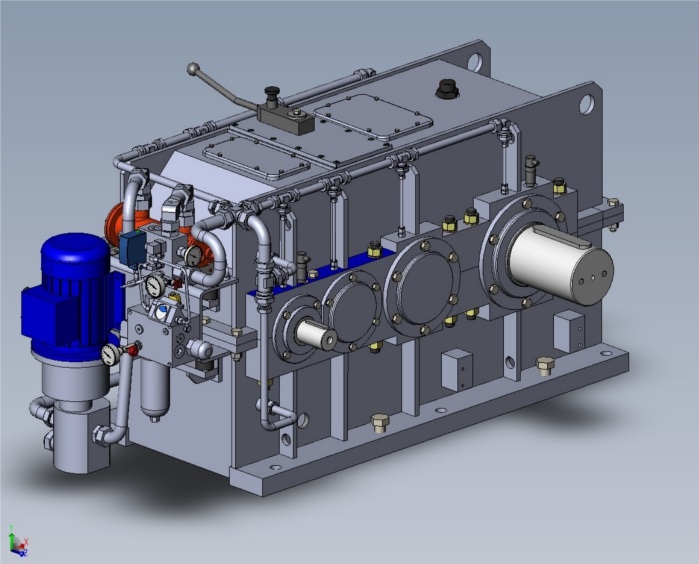

(Parallel shafts gearbox with oil supply system)

Our company is characterized by its ability to manage internally all the production cycle, from the design to the machining operations and assembly.

Our know-how is based upon the practical experience accumulated through the multitude of applications developed during our activity, and thanks to the preparedness and continuous improvement of our engineers and of our technical resources.

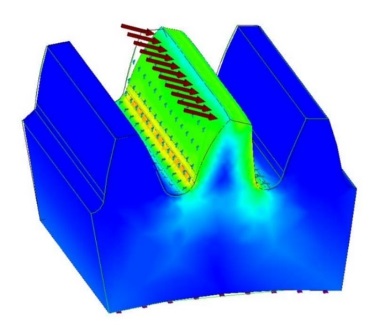

In our field of activity, characterized by a constant evolution of technology and standards, it is of decisive importance to follow step-by-step the innovations and to gain access to state-of-the-art machinery and devices.

The 2D/3D CAD workstations of our Technical Department, for example, use the latest resources for drafting and modeling, thus allowing us to design with the utmost care to details and contributing to achieve a high quality product.

(Finite elements analysis of a gear)