Special production

Thanks to more than 60 years of experience in engineering and manufacturing custom made gearboxes for most applications, our company can offer the ideal solution to every problem of mechanical power transmission, fulfilling the needs of our customers in terms of functionality, reliability and economy of operation.

The most important industrial sectors in which our gearboxes are applied are:

- steel, aluminum and non ferrous metal industry

- paper industry

- power stations

- material handling

- rubber and plastic industry

- oil & gas

- cement and minerals industry

- sugar and food industry

- pumping stations and water treatment plants

According to the customers’ needs, it is possible to develop special solutions starting from catalogue products, as well as to design a completely special product based upon a technical specification.

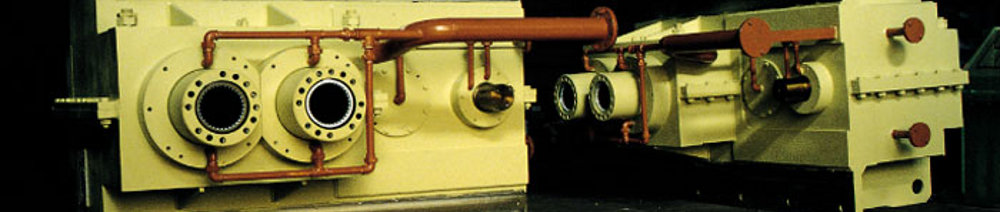

(Gearbox for coiler, with sliding baseplate)

All our products are engineered and manufactured according to the latest standards in design and manufacturing, and depending upon the specific needs the following details may be included:

- helical, double helical or straight teeth gears, made of high grade alloy steel, case hardened, tempered and ground on the teeth profile, or made of through hardened alloy steel, or even nitrided or induction tempered

- gleason or Klingelnberg type bevel gears, case hardened, tempered and ground or lapped on the teeth profile

- gears calculated according to AGMA / DIN / ISO Standards

- gearboxes can be designed also according to API 677 (with deviations), CTI, ATEX Standards

- casings for catalogue products made of cast iron up to and including size 280, and from size 320 in welded steel (Fe 430 B), stress relieved before machining.

- casings for custom made gearboxes made of welded steel (Fe 430 B) , stress relieved before machining

- the reducers casings are provided with vent and oil filling plug, oil level sight glass and inspection hatch, as well as stiffening ribs and hoisting holes or hooks. It is always possible to provide extra holes and fittings for the application of any type of sensors for continuous monitoring of the gearbox operating conditions.

- all casings can also be made of steel with high impact strength, suitable for operation at very low temperatures

-

baseplates can be provided:

- to support motors, couplings, brakes and other accessories

- fixed or sliding by means of hydraulic cylinders

-

oil lubrication can be:

- by oil splash

- by forced circulation of oil coming from an onboard system

- by forced circulation of oil coming from a centralized supply system

- all bearings are from top quality brands, purchased directly from the manufacturers

- low speed shafts made of through hardened steel, with key or spline or, in case of hollow shafts, with key or shrink disks

- a quality control plan is also supplied, including the certificates of origin of the raw materials, the certificates of the heat treatments as well as those regarding the tests performed on the components and on the assembled gearbox

- every gearbox is subjected to a no-load running test during which temperature, vibration and noise are recorded