Quality control

ELLI has been operating under certified quality assurance procedures, according to UNI EN ISO 9001 standards, since 1993.

The raw materials are purchased from selected suppliers, complete of the relevant certificates, and are checked at their delivery to our workshop.

The product quality is ensured by a series of tests along the line of production, during the manufacture of the different parts, as well as by the visual and dimensional check on every finished part.

Furthermore, the most important parts (pinions and gears) are subjected to ultrasonic test and to hardness test after heat treatment.

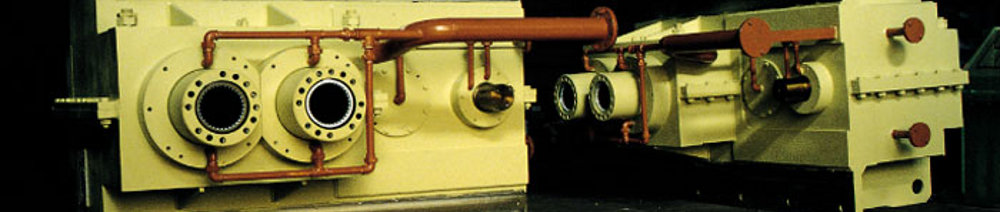

Every reducer, after assembly, is subjected to a final check and to a no-load test at its actual operating speed and in its actual operating position for a time long enough to allow for temperature stabilisation.

During the final check on the assembled reducer it is our common practice to:

- measure the bearing clearance;

- measure the contact pattern width between the mating teeth;

- measure the oil and bearings temperatures

- measure the sound pressure level (dBA at 1 m);

- measure the vibration velocity (mm/s) at various points of the casing;

- check the seals tightness;

- test the centralized lubrication unit, if present.

Upon request, it is possible to supply a copy of the materials certificates and of the tests performed; it is also possible to perform other checks and tests, to be agreed upon when ordering.